Categories List

Product Description

Low power consumption, stable and reliable, fully automated production

The company has mastered the core technology of pressure swing adsorption oxygen production, and has achieved breakthrough research results in core components - gas molecular sieves, adsorption towers, and blowers. It has the ability to manufacture oxygen production systems with ultra-high purity, ultra-high stability, and low noise levels.

Intelligent low consumption

1. Low power consumption for oxygen production

The power consumption of pure oxygen produced by the traditional cryogenic method is between 0.6 and 1.0 degrees. Our VPSA pressure swing adsorption oxygen production system uses all-lithium-based molecular sieves, which use a large amount of molecular sieves, so the power consumption of pure oxygen is between 0.28 and 0.32 degrees.

2. Simple operation and high degree of automation

One motor and 11 valves are needed to realize fully automatic oxygen production, without any human intervention.

3. Low auxiliary costs such as water, floor space, and labor

The water consumption of the same scale is one-third of that of traditional cryogenics, the floor space is half of that of traditional cryogenics, and the number of employees is one-quarter of that of traditional cryogenics.

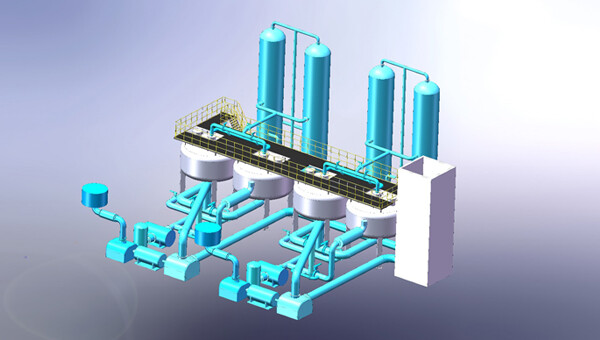

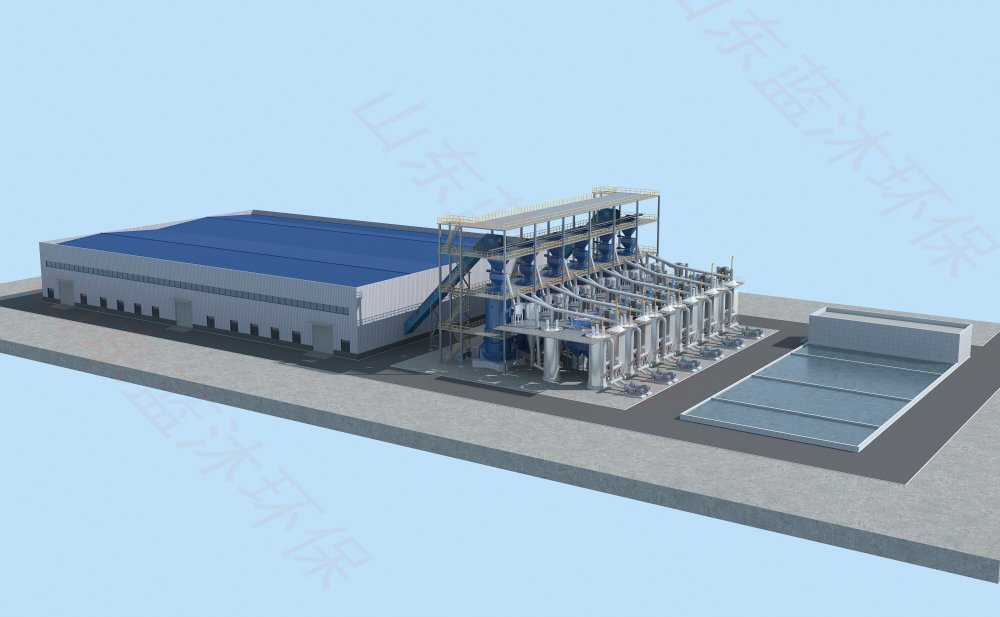

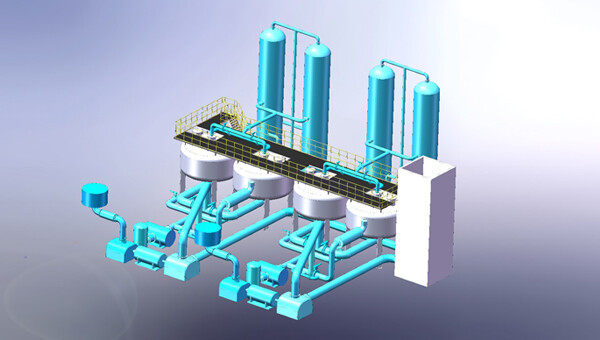

Full 3D design

For each project, we will give detailed design from the aspects of process, equipment, civil engineering plant and sound insulation and noise reduction, and provide detailed design and construction drawings. All designs are three-dimensional. In order to provide tailor-made services for industries such as steel, cement, nonferrous metals, electricity, and environmental protection, our company has a number of professionals in each industry to connect with customers.

Acoustic field and flow field simulation

The adsorption tower is divided into axial tower and radial tower according to the direction of adsorption airflow. Our company selects the design according to the scale of the device, the site and other conditions. Professional computer fluid simulation software is used in the design process, and the airflow distribution is reasonable with less dead zone.

Sound insulation and noise reduction

Noise is the primary problem to be overcome in large-scale multi-set PSA parallel oxygen supply. Our company draws on the noise reduction technology of submarines and relies on the domestic advanced national defense noise reduction laboratory. We first conduct professional measurement and analysis of the noise on site, and adopt different noise reduction schemes for sound waves of different frequencies according to the characteristics of the pop.

Advantages of Molecular Sieve

The largest molecular sieve production base in China

The most automated molecular sieve production base in China

The most standardized molecular sieve production base in China with strict quality control

Common specifications and models of equipment

Related products

Message

What are you lookking for?