Categories List

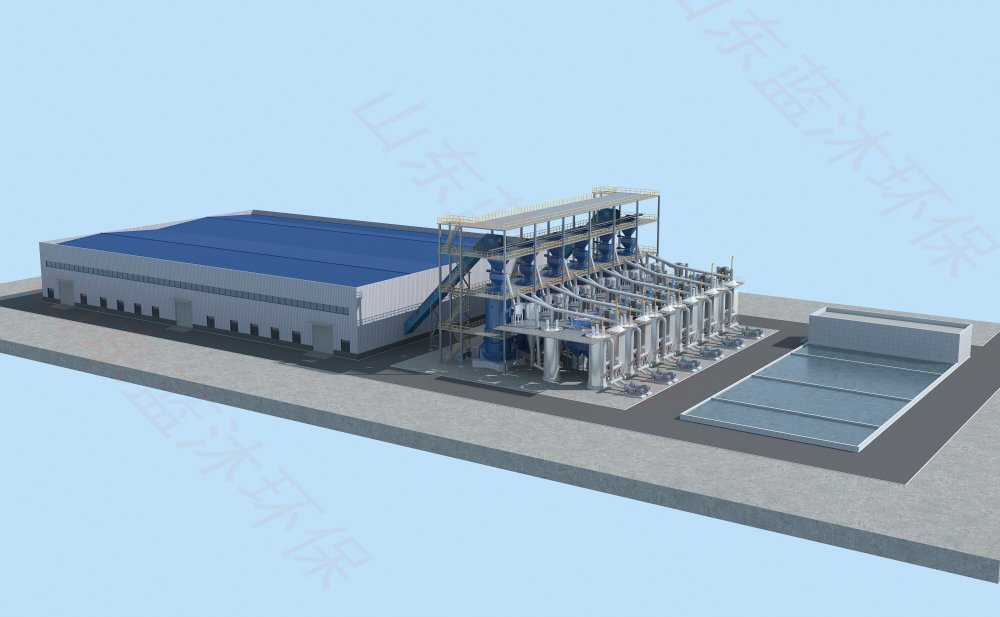

Product Description

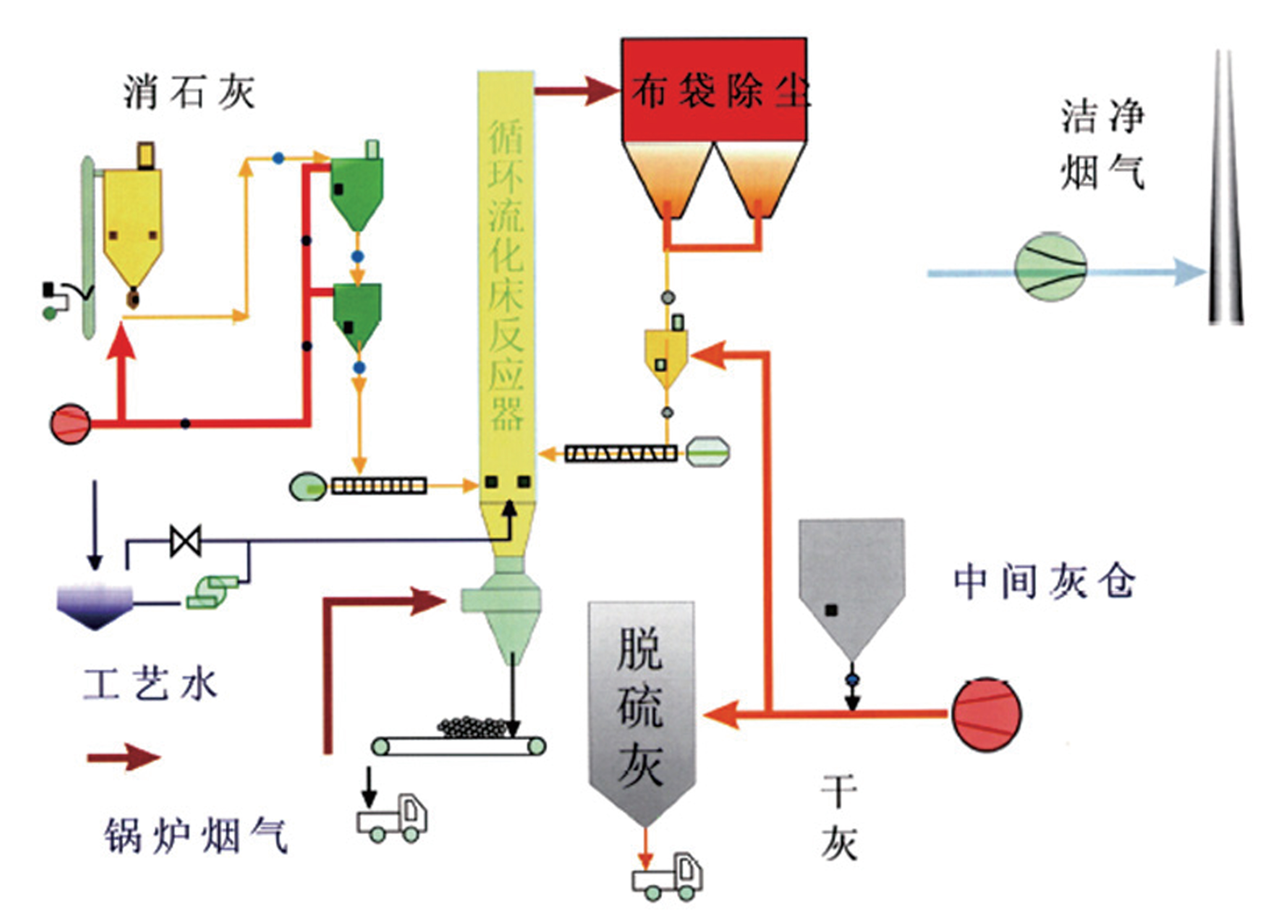

Reaction principle:

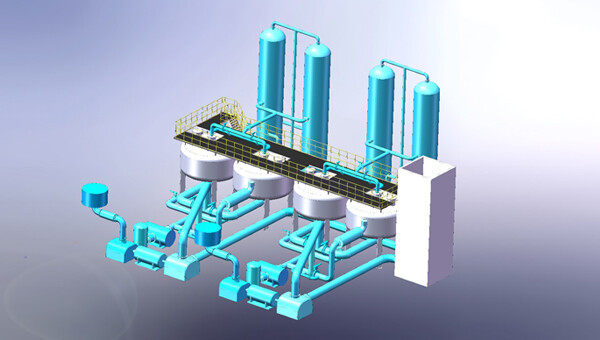

The chemical principle of CFB semi-dry flue gas desulfurization is that Ca(OH)2 powder and acid gases such as SO2, SOs, HCI, HF in the flue gas are fully mixed and reacted in the flue gas circulating fluidized bed in the presence of water to achieve efficient desulfurization. This process has been widely used in power plants, smelters, steel mills, waste incineration plants and other fields in Germany, Austria, Poland, Czech Republic, the United States, Ireland, China and other countries. The largest operating single tower unit has a capacity of 300MW.

CFB Flue Gas Desulfurization Advantages:

(1) High desulfurization efficiency: SO2 removal efficiency can reach 99%, and HCI, HF, etc. can be removed at the same time;

(2) High desulfurization agent utilization rate: The circulation ratio reaches 80, and the desulfurization agent is fully utilized;

(3) The moisture content of the desulfurization agent is very low, no agglomeration, and no corrosion;

(4) Stable performance: The high circulation of a large amount of active absorbent in the tower makes the desulfurization efficiency quite stable;

(5) Strong adaptability: It can be used for different SO2 content and process load changes;

(6) The absorbent is cheap;

(7) The operating temperature is higher than the dew point, and there is no corrosion or condensation;

(8) No wastewater is generated. Since the exhaust temperature is higher than the flue gas acid dew point temperature, and since the desulfurization process can absorb almost all SOs in the flue gas, there is no need for special anti-corrosion treatment of the flue gas duct, induced draft fan and smoke after desulfurization;

(9) The flue gas can be discharged without reheating, and there is no white smoke at the outlet of the smoke map.

Related products

Message

What are you lookking for?